Key Trends in the Work Alone Safety Market:

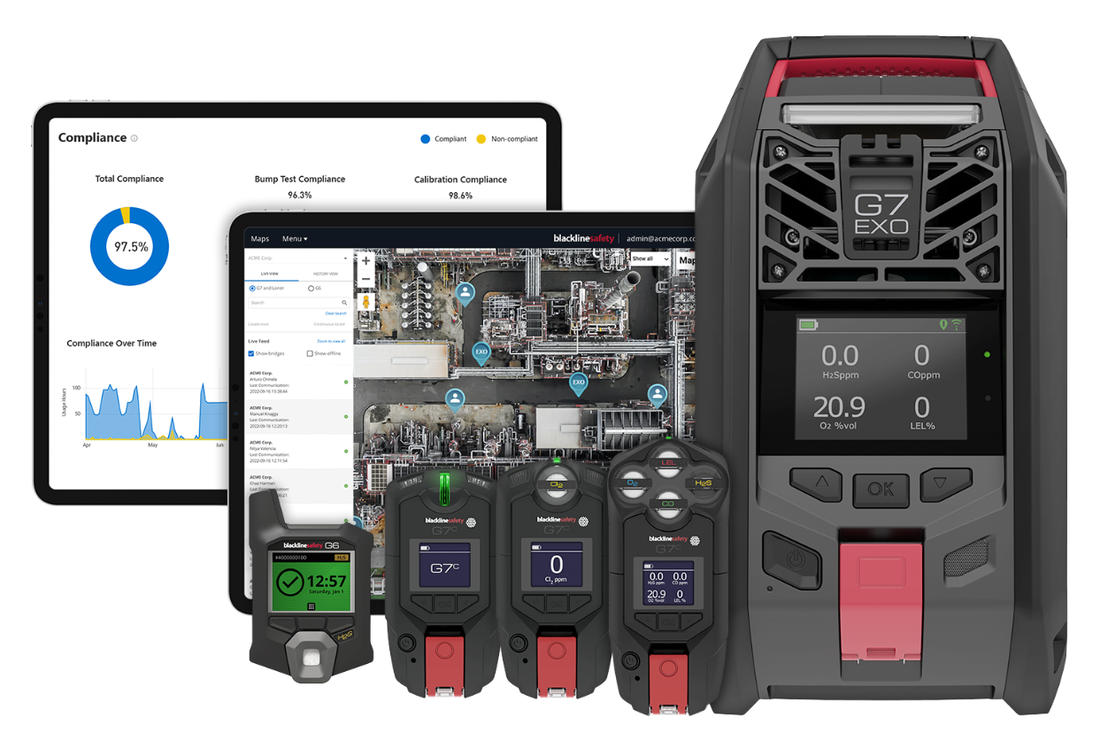

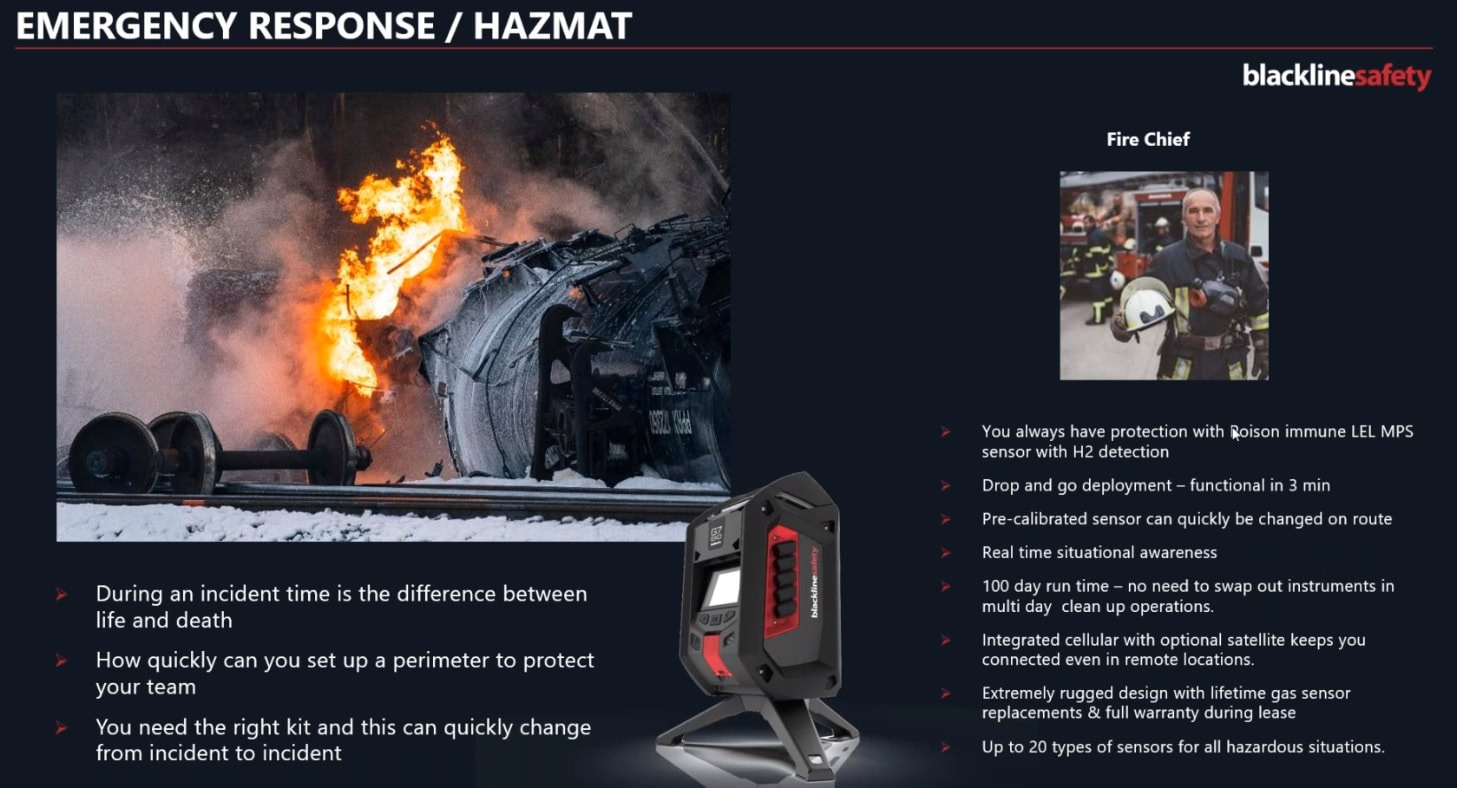

- 📈 Growing Adoption of Wearable Safety Technology – Devices with fall detection, no-motion alerts, and GPS tracking are becoming industry standards.

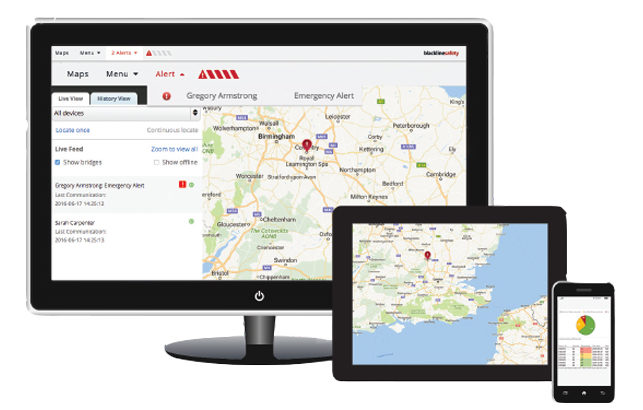

- 🔄 Real-Time Monitoring & Automated Check-Ins – Companies are implementing cloud-based lone worker monitoring systems to ensure safety compliance.

- 📡 AI & IoT Integration – Smart sensors and AI-driven analytics enhance work alone safety solutions, improving response times and risk assessment.

- 🌍 Expanding Regulatory Requirements – Governments worldwide are tightening workplace safety laws, increasing demand for compliant lone worker safety devices.

BLACKRIDGE Solutions: Leading the Way

At BLACKRIDGE Solutions, we stay ahead of the curve by providing state-of-the-art work alone safety products designed for industries like construction, utilities, healthcare, oil & gas, and transportation.

Explore the latest lone worker safety innovations today! Contact us today at: [email protected]

RSS Feed

RSS Feed