In this article, we will explore the safety considerations specific to the oil and gas industry and demonstrate how our state-of-the-art gas detection and lone worker safety products can effectively address these concerns. Moreover, we will discuss the essential role that advanced technology plays in fostering a culture of safety, enhancing operational efficiency, and achieving regulatory compliance within the oil and gas industry.

Mitigating Risks and Enhancing Safety in the Oil and Gas Industry with Advanced Gas Detection and Lone Worker Solutions

Detection and Monitoring of Hazardous Gases in Oil and Gas Operations

The oil and gas facilities are exposed to a wide range of hazardous gases, such as hydrogen sulfide, methane, and carbon monoxide. Advanced gas detection and monitoring systems offer numerous advantages to managing the risks associated with these gases:

1. Continuous Monitoring and Real-Time Alerts: Modern gas detectors provide constant monitoring of potentially dangerous gases, delivering up-to-date data and essential alerts to workers and facility managers.

2. Customizable and Scalable Solutions: Flexible gas detection systems can be tailored to meet the distinct requirements of oil and gas operations, ensuring that specific safety needs are adequately addressed.

3. Regulatory Compliance: High-quality gas detection devices boast superior accuracy and reliability, helping oil and gas facilities conform to industry regulations and maintain strict safety standards.

Comprehensive Lone Worker Safety Solutions for Oil and Gas Workers

Oil and gas workers often operate in remote, inaccessible, or challenging environments, warranting robust safety infrastructure and reliable communication tools. Key features of lone worker safety devices designed for the oil and gas sector include:

1. GPS Tracking and Real-Time Monitoring: Safety devices equipped with GPS technology offer real-time location data and emergency assistance, providing indispensable support for worker safety throughout oil and gas operations.

2. Instant Communication and Emergency Alerts: Safety devices with instantaneous communication capabilities and emergency buttons enable workers to quickly notify their colleagues or supervisors of potential threats, facilitating immediate response and support.

3. Worker Well-being Monitoring: Advanced devices with automated check-ins allow supervisors to keep track of their employees' well-being, ensuring tasks are carried out safely and efficiently.

Establishing and Implementing Safe Operating Procedures in Oil and Gas Operations

Developing and enforcing strict operating protocols, coupled with continuous employee training, are essential components for maintaining a safe work environment and preventing accidents within the oil and gas industry:

1. Hazard Identification and Risk Assessment: Conducting comprehensive hazard assessments and establishing clear risk management strategies form the foundation for an effective safety strategy that caters to the specific needs of oil and gas operations.

2. Employee Training and Education: Delivering regular training on safe work procedures, hazard recognition, and emergency response helps cultivate a safety-conscious workforce.

3. Routine Inspections and Assessments: Systematic equipment inspections and facility assessments are crucial in ensuring ongoing compliance and preventing incidents caused by equipment failure or procedural deficiencies.

Boosting Operational Efficiency with Innovative Safety Solutions

Utilizing advanced gas detection and lone worker safety solutions in oil and gas operations not only improves worker safety but also enhances operational efficiency:

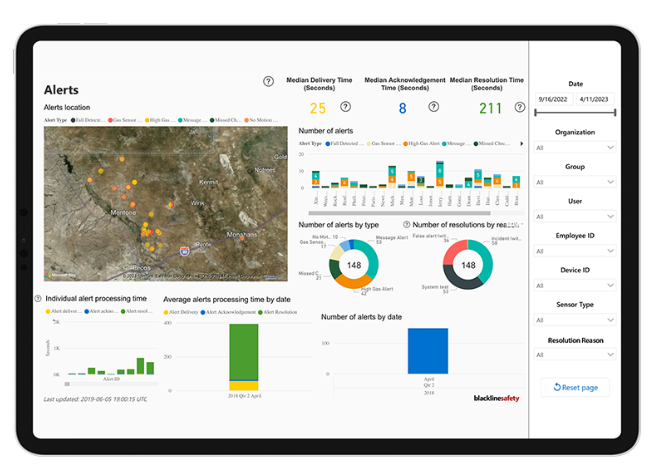

1. Data-Driven Decision-Making: Valuable insights generated by gas detectors and safety devices deliver actionable information on potential hazards and areas of inefficiency, empowering decision-makers to implement strategic improvements

2. Reduced Maintenance and Downtime: Continuous and accurate gas detection monitoring enables oil and gas facilities to schedule maintenance activities more effectively, reducing equipment downtime and preventing unexpected breakdowns.

3. Fostering a Culture of Safety: Demonstrating a commitment to worker safety by implementing the latest safety solutions helps foster a safety-conscious culture and positively impacts morale, productivity, and employee retention.

Embracing Advanced Safety Solutions in Oil and Gas Operations

The oil and gas industry, with its complex operating conditions and unique hazards, demands the adoption of advanced gas detection and lone worker safety systems. By incorporating these innovative technologies, oil and gas facilities can reduce risks, enhance operational efficiency, and maintain a safe working environment for employees.

Equip your oil and gas facility with industry-leading gas detection and lone worker safety devices from BLACKRIDGE Solutions. Protect your workers with reliable safety solutions and ensure your organization's ongoing success in 2024 and beyond. For more information, contact us at: (778) 686-5799 or [email protected]

RSS Feed

RSS Feed