In this article, we will explore the fundamental safety considerations associated with chemical plants and demonstrate how our state-of-the-art gas detection and lone worker safety products can effectively address these concerns. We will also outline the essential role of innovative technology in promoting a culture of safety, enhancing operational efficiency, and achieving regulatory compliance within the chemical industry.

Our aim with this article is to encourage leaders in the chemical plant industry to invest in advanced gas detection and lone worker safety solutions. Adopting these innovative technologies is a powerful way to create safer workplaces for employees while meeting stringent industry requirements.

Maximize worker safety at your chemical plant with industry-leading gas detection and lone worker safety devices from BLACKRIDGE Solutions, ensuring the protection and well-being of your employees in 2024 and beyond.

Detection and Monitoring of Hazardous Gases and Chemicals in Chemical Plants

Chemical plant employees often face potential hazards resulting from exposure to dangerous materials. Implementing advanced gas detection and monitoring systems offers several advantages:

- Continuous Monitoring and Real-time Alerts: Sophisticated gas detectors provide constant monitoring of hazardous gases and chemicals, delivering up-to-date data and critical alerts to protect workers from exposure and maintain environmental safety standards.

- Customizable and Adaptable Solutions: Scalable gas detection systems can be tailored to accommodate the unique requirements of chemical plants, ensuring their specific safety needs are met.

- Regulatory Compliance: High-quality gas detection devices offer superior accuracy and reliability, helping chemical plants adhere to industry regulations and maintain exceptional safety standards.

Comprehensive Lone Worker Safety Solutions for Chemical Plant Workers

Chemical plant workers may sometimes operate in remote or isolated areas, necessitating robust safety infrastructure and reliable communication tools. Key features of lone worker safety devices include:

- GPS Tracking and Real-Time Monitoring: GPS-enabled safety devices offer real-time location data and emergency assistance, providing essential support for worker safety in any part of the facility.

- Instant Communication and Emergency Alerts: Safety devices with instant communication capabilities and emergency buttons enable workers to promptly inform their colleagues or supervisors of potential threats, facilitating immediate response and support.

- Worker Well-being Supervision: Advanced devices with automated check-in functions allow supervisors to monitor their employees' well-being, ensuring tasks are completed safely and efficiently.

Implementing Safe Operating Procedures in Chemical Plants

Adhering to strict operating procedures and continuous employee training play vital roles in maintaining a safe working environment and reducing incidents in chemical plants:

- Hazard Identification and Risk Assessment: Conducting thorough hazard assessments and establishing clear risk management protocols is crucial in creating an effective safety strategy tailored to the specific needs of chemical plants.

- Employee Training and Education: Regularly providing comprehensive employee training on safe work procedures, hazard recognition, and emergency response helps foster a safety-conscious workforce.

- Routine Inspections and Assessments: Performing systematic equipment inspections and facility assessments ensures ongoing compliance, helping prevent incidents caused by equipment failure or procedural deficiencies.

Boosting Operational Efficiency with Innovative Safety Solutions

Employing advanced gas detection and lone worker safety solutions in chemical plants not only improves worker safety but also enhances operational efficiency:

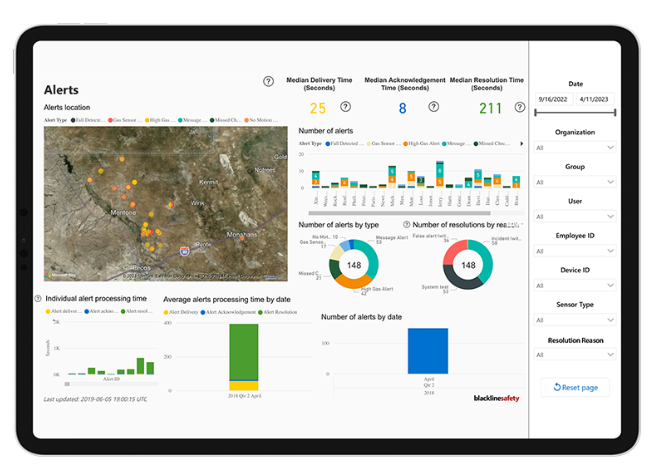

- Data-Driven Decision-Making: Valuable insights generated by gas detectors and safety devices provide actionable information on potential hazards and areas of inefficiency, empowering decision-makers to make strategic adjustments.

- Reduced Maintenance and Downtime: Uninterrupted and accurate gas detection monitoring enables facilities to schedule maintenance more effectively, minimizing equipment downtime and preventing unexpected malfunctions.

- Fostering a Culture of Safety: Demonstrating a commitment to worker safety by implementing modern safety solutions helps nurture a safety-conscious culture, positively impacting morale, productivity, and employee retention.

Adopting Advanced Safety Solutions in Chemical Plants

Chemical plants, given their complex environments, face numerous safety challenges that warrant the adoption of advanced gas detection and lone worker safety systems. By embracing these innovative technologies, chemical plants can mitigate risks, enhance operational efficiency, and maintain a safe working environment for employees.

Equip your chemical plant with industry-leading gas detection and lone worker safety devices from BLACKRIDGE Solutions. Protect your employees with reliable safety solutions and ensure your organization's ongoing success in 2024 and beyond. Contact us today at (778) 686-5799 or [email protected]!

RSS Feed

RSS Feed