In this article, we will delve into the safety challenges faced by the mining industry and demonstrate how our cutting-edge gas detection and lone worker safety products can support mining companies in establishing effective safety protocols, protecting employees, and adhering to industry regulations. Additionally, we will shed light on the influence of innovative technologies in improving operational efficiencies and showcase the benefits that span both employee safety and overall business performance.

By offering valuable insights into how our state-of-the-art gas detection and lone worker safety technologies are transforming safety practices in the mining industry, this article aspires to inform and inspire mining organizations to adopt innovative safety solutions tailored to their unique needs and challenges.

Optimizing Hazardous Gas Detection in the Mining Industry

Mining personnel are frequently exposed to hazardous gases, such as methane and carbon monoxide. Establishing efficient gas detection and monitoring systems is imperative to maintain a safe mining environment. Integrating advanced gas detection technologies offers several advantages:

1. Comprehensive Monitoring and Real-time Alerts: State-of-the-art gas detectors monitor potentially hazardous gases continuously, delivering real-time data and critical alerts to safeguard workers from excessive exposure or life-threatening situations.

2. Customizable and Scalable Solutions: Cutting-edge gas detection systems provide extensive customization and scalability options, allowing companies to configure their safety solutions according to their specific requirements and operational needs.

3. Regulatory Compliance: Ensuring adherence to industry regulations is vital for the mining sector. Advanced gas detection equipment guarantees accurate results, giving mining companies confidence that they are meeting compliance standards.

Lone Worker Safety in the Mining Industry

Owing to the nature and vastness of mining sites, workers are often stationed in remote or isolated locations. This scenario calls for robust lone worker safety solutions to guarantee employees' protection:

1. GPS Tracking and Real-time Monitoring: GPS tracking devices provide real-time location data and emergency assistance, allowing mining companies to maintain high safety standards even in remote areas.

2. Instant Communication and Emergency Alerts: Lone worker safety devices equipped with instant communication features and emergency buttons allow miners to quickly notify supervisors of distressing situations, enabling prompt intervention.

3. Worker Well-being Supervision: Advanced safety devices with automated check-in capability help supervisors monitor the well-being of workers, ensuring they are performing their tasks safely and efficiently.

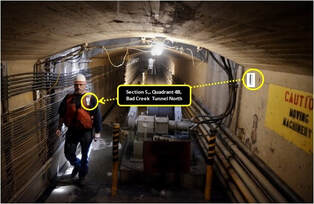

Mitigating Confined Space Hazards in the Mining Industry

Confined spaces in mining facilities present unique risks for employees, primarily due to limited access and the possibility of gas accumulation. Implementing comprehensive safety measures can alleviate these dangers:

1. Specialized Gas Detectors: Portable gas detection devices designed for confined spaces empower workers with accurate gas-level monitoring, ensuring environments are safe for entry and reducing the risk of incidents.

2. Confined Space Entry and Exit Protocols: Establishing rigorous entry and exit procedures for confined spaces, paired with thorough employee training, is crucial to preventing accidents and injuries.

3. Ventilation and Engineering Controls: Investing in adequate ventilation systems and other engineering controls to mitigate gas buildup in confined spaces elevates safety and enhances employees' well-being in the mining industry.

Improvements in Operational Efficiency through Advanced Safety Solutions

Adopting cutting-edge gas detection and lone worker safety solutions not only ensures safety compliance but also improves the overall efficiency of mining operations:

1. Data-Driven Decision Making: The insights generated by gas detectors and safety devices provide key information on potential risks and operational inefficiencies. By leveraging these data points, management can make informed decisions and adapt their safety strategies accordingly.

2. Reduced Maintenance and Downtime: Consistent and precise gas detection monitoring allows mining companies to schedule maintenance more efficiently and minimize downtime due to equipment malfunctions or failures.

3. Fostering a Culture of Safety: Demonstrating a commitment to employee safety by equipping workers with advanced safety solutions fosters a culture of safety, translating into higher morale, productivity, and reduced turnover rates.

The Significance of Advanced Safety Solutions in the Mining Industry

The mining industry faces a unique set of safety challenges, necessitating state-of-the-art gas detection and lone worker safety systems to ensure employees' well-being. By investing in these next-generation safety technologies, mining companies can safeguard their workforce while simultaneously enhancing operational efficiency, fostering a secure and productive work environment.

Elevate the safety standards of your mining operation by integrating industry-leading gas detection and lone worker safety technologies from BLACKRIDGE Solutions. Protect your miners with dependable safety solutions and ensure the ongoing success of your company in 2024 and beyond. For more information, contact BLACKRIDGE Solutions at (778) 686-5799 or [email protected]

RSS Feed

RSS Feed