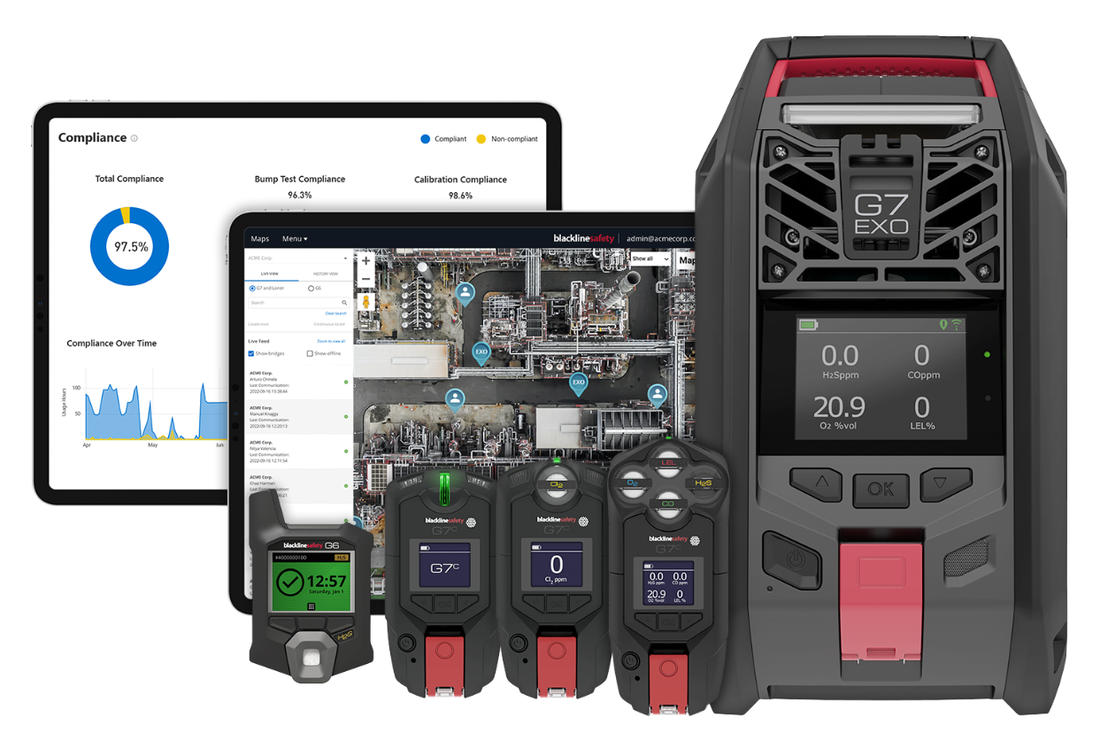

BLACKRIDGE Solutions, a leader in lone worker safety and gas detection solutions, offers a comprehensive and award-winning product portfolio designed to meet these challenges. Products such as the G7 Gas Detection & Monitoring System and the Loner series aim to provide employees in the warehousing industry with the protection and confidence they need to perform their tasks safely.

In this article, we will explore how our advanced gas detection and lone worker safety technologies can enhance employee safety and operational efficiency within the warehousing sector. By integrating these innovative systems into existing safety protocols, warehousing facilities can effectively safeguard employees, maintain regulatory compliance, and improve productivity, ultimately contributing to a safer and more secure workplace environment.

Effective Gas Detection Solutions for the Warehousing Industry

To uphold employee safety and maintain regulatory compliance, warehouses must monitor and control gas concentrations within their facilities, especially in areas containing hazardous substances. We provide sophisticated gas detection equipment designed to meet these needs:

1. Real-time Gas Monitoring and Alerts: The G7 Gas Detection & Monitoring System continually measures gas concentrations and provides instant alerts to employees and supervisors, enhancing safety and enabling rapid responses to potential hazards.

2. Compliance with Regulatory Standards: Warehousing facilities must adhere to stringent industry regulations to ensure workplace safety. By utilizing advanced gas detection technologies, they can demonstrate their commitment to surpassing industry standards for employee protection.

3. Data-driven Decision Making: The valuable data generated by BLACKRIDGE Solutions’ gas detection systems enable warehousing operators to refine safety protocols, allocate resources strategically, and update training programs based on accurate information.

Elevating Lone Worker Safety in Warehousing Environments

Warehouse workers often perform tasks independently or in remote sections of the facility, necessitating appropriate safety measures such as lone worker monitoring devices and reliable communication systems. We offer the Loner series to address these challenges:

1. Real-time GPS Location Tracking: Advanced tracking technology integrated into our devices enables supervisors to monitor employee locations continuously, expediting emergency response times and ensuring lone workers can access support when needed.

2. Automatic Alerts for Fall and No-motion Detection: Innovative sensors detect changes in employee activity, such as falls or extended periods of inactivity, triggering automatic alerts that enable relevant personnel to provide prompt assistance.

3. Accessible Panic Button for Immediate Help: Lone worker safety devices feature easily accessible panic buttons, empowering employees to request rapid assistance in emergency situations.

4. Reliable Two-way Communication: Consistent communication channels between warehouse workers and supervisors facilitate real-time situational awareness and offer crucial support during potential safety incidents.

Addressing Confined Space Safety in Warehousing Facilities

Warehousing environments often include confined spaces where risks of gas exposure and limited mobility can be significant. We cater to these needs by providing the following:

1. Tailored Confined Space Gas Detection Systems: Portable gas detection systems designed for confined space use are lightweight and easily transportable, enabling workers to monitor gas concentrations effectively in these restrictive environments.

2. Comprehensive Training and SOP Development: Employees must receive extensive training on confined space entry and rescue procedures, and facilities must have clear standard operating procedures (SOPs) in place to ensure optimal safety in confined spaces.

3. Enhanced Atmospheric and Worker Monitoring: Advanced monitoring systems designed for confined space environments help maintain optimal atmospheric conditions while monitoring worker safety in real time, providing essential data for decision-making during potential emergencies.

Improving Warehousing Efficiency with BLACKRIDGE Solutions

Our cutting-edge gas detection and lone worker safety technologies not only protect warehouse employees but also contribute to increased operational efficiency:

1. Streamlined Monitoring and Control of Gas Concentrations: Seamless integration of advanced gas detection systems with overall facility control systems enables continuous atmospheric monitoring and alerts, allowing supervisors to make informed decisions quickly.

2. Efficient Troubleshooting and Maintenance: Data generated by gas detection systems aid in the early identification of potential issues, facilitating preventive maintenance and streamlining troubleshooting efforts.

3. Enhanced Operational Efficiency: Constant monitoring of gas concentrations within the workplace contributes to the identification of inefficiencies and potential hazards, providing opportunities for process optimization and overall performance improvement.

Empowering Warehousing Employees with BLACKRIDGE Solutions

By embracing our advanced lone worker safety and gas detection technologies, warehousing facilities can provide employees with the protection they need to perform their tasks safely and confidently. Integrating these innovative systems into existing safety protocols safeguards employee well-being, enhances regulatory compliance, and improves operational efficiency.

Invest in BLACKRIDGE Solutions’ superior safety technologies for your warehousing workforce and ensure a safer, more productive workplace environment. Contact us today at (778) 686-5799 or [email protected] to learn about our respected and award-winning lone worker safety systems and how we can elevate your facility's safety standards.

RSS Feed

RSS Feed