In this blog post, we will explore the unique challenges associated with remote worker safety and discuss how BLACKRIDGE Solutions' technologies are specifically designed to address these concerns. By examining their state-of-the-art gas detection and lone worker safety devices, we will demonstrate the value of partnering with BLACKRIDGE Solutions for creating a safer and more secure work environment, regardless of location or industry. Additionally, we will provide insights on best practices for effectively implementing remote worker safety solutions, highlighting the essential role that BLACKRIDGE Solutions' technology plays in promoting a culture of safety and preparedness.

Challenges of Remote Worker Safety

Remote work environments come with a unique set of safety challenges, when compared to traditional office settings. These challenges include:

1. Limited Supervision: In remote locations, employees may work without direct supervision, making it harder to address safety concerns in a timely manner.

2. Communication Difficulties: Remote workers may experience communication barriers, due to lack of connectivity or geographic isolation.

3. Environmental Hazards: Remote work environments may expose employees to harsh weather conditions, potentially affecting their well-being and safety.

4. Exposure to Hazardous Gases: Workers operating in industries such as oil and gas or chemical plants may encounter dangerous gases, creating potentially life-threatening situations.

In response to these challenges, BLACKRIDGE Solutions offers cutting-edge technologies that effectively address the safety needs of remote workers.

Advanced Gas Detection Solutions

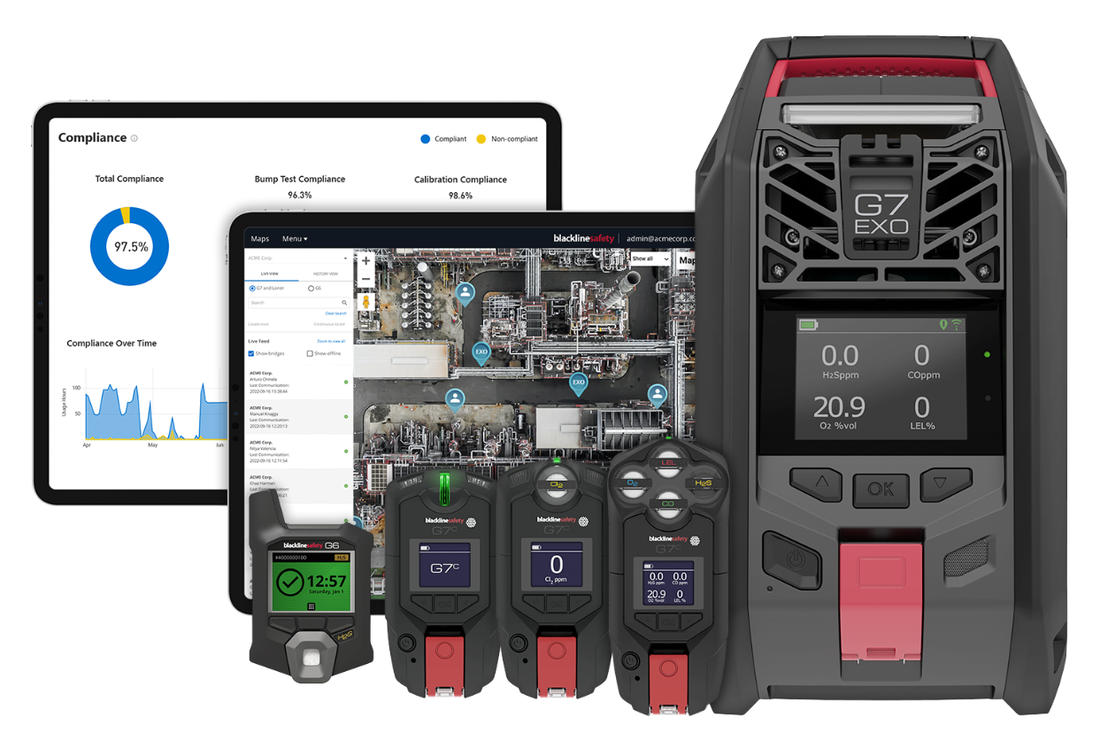

One of the most significant risks remote workers may face is the exposure to hazardous gases. To minimize this risk, BLACKRIDGE Solutions provides state-of-the-art gas detection devices, such as the G7 Gas Detection & Monitoring System. This advanced technology ensures the following:

1. Real-Time Gas Monitoring: The G7 system continuously monitors the environment for hazardous gases, alerting employees and supervisors in real-time of any potential dangers.

2. Wireless Connectivity: The system's wireless capabilities enable remote monitoring and updates, eliminating the need for manual calibration and ensuring accurate readings at all times.

3. Customizable Alarms and Thresholds: The G7 system can be customized to suit the specific needs of your business, with adjustable alarms and gas detection thresholds.

4. Rapid Emergency Response: In the event of a gas leak or exposure, the system's emergency response feature ensures swift assistance, helping to prevent severe health issues or fatalities.

Lone Worker Safety Devices and Systems

Another essential element of remote worker safety is providing employees with effective lone worker safety devices and systems. BLACKRIDGE Solutions' suite of products, including the Loner series by Blackline Safety, offers comprehensive protection for remote workers, encompassing:

1. Real-Time Location Tracking: With GPS and indoor location tracking technology, employers can monitor the whereabouts of their remote workers, ensuring timely assistance in case of an emergency.

2. Fall and No-Motion Detection: Integrated sensors can detect falls or lack of movement, alerting monitoring personnel to potential accidents or emergencies.

3. Panic Button: The Loner series includes a panic button that can be activated by the employee in case of emergency, enabling rapid response and assistance.

4. Two-Way Communication: These devices facilitate two-way communication with monitoring personnel, providing support in emergency situations and contributing to workers' peace of mind.

Best Practices for Implementing Remote Worker Safety Solutions

While incorporating advanced safety technologies is essential, businesses must also adopt best practices for optimizing the effectiveness of these remote worker safety solutions. These best practices include:

1. Risk Assessment: Conduct a thorough risk assessment to identify potential hazards and safety concerns within your remote work environment.

2. Employee Training: Invest in comprehensive training efforts, ensuring employees understand the operation of safety devices, risk mitigation techniques, and emergency response procedures.

3. Regular Equipment Maintenance: Ensure that all safety devices, such as gas detectors and lone worker systems, undergo regular maintenance to guarantee accurate readings and optimal performance.

4. Continuous Improvement: Continuously review and update remote worker safety plans, adopting new technologies and practices when available to ensure maximum employee protection.

Empowering Remote Workers with BLACKRIDGE Solutions

As remote work becomes more prevalent, businesses bear the responsibility of ensuring the safety and well-being of their employees, regardless of location. By leveraging BLACKRIDGE Solutions' advanced gas detection and lone worker safety technologies, organizations can address the unique challenges associated with remote work environments effectively.

In addition to employing cutting-edge devices, businesses should also follow industry best practices to create a safe working environment for their remote employees. Implementing comprehensive plans that include risk assessments, training efforts, and equipment maintenance will further enhance the value of BLACKRIDGE Solutions' innovative technologies.

By partnering with BLACKRIDGE Solutions and focusing on the safety needs of remote workers, businesses can create an environment where employees feel secure, supported, and empowered to deliver their best work. Contact BLACKRIDGE Solutions today (778) 686-5799 or [email protected] to discover how their lone worker solutions can transform your remote worker safety program.

RSS Feed

RSS Feed