Introduction:

The agricultural sector is the foundation of global food systems, contributing significantly to economic growth and sustenance for billions worldwide. While farming provides essential resources for human survival, those working in the industry face numerous occupational hazards, spanning pesticide exposure, unsafe heavy machinery operation, and encounters with hazardous gases. Agricultural workers, particularly those operating independently on vast farms, require additional safety measures to navigate the risks associated with their remote work environments. Consequently, it is paramount for agricultural companies to adopt advanced safety technology and best practices designed to safeguard workers and improve overall workplace safety.

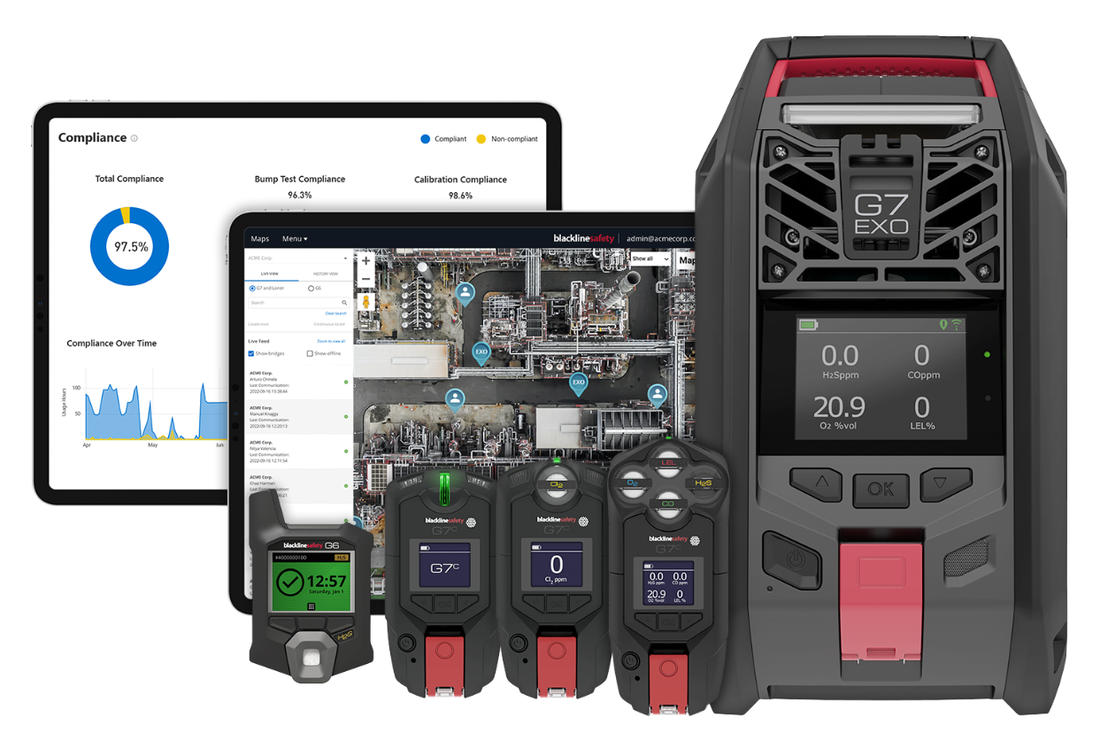

BLACKRIDGE Solutions, a trailblazer in lone worker safety and gas detection systems, offers a distinguished and award-winning product portfolio designed to address the unique safety challenges faced by employees across diverse industries, including agriculture. By rigorously testing and handpicking innovative devices from industry-leading manufacturers and developers, BLACKRIDGE Solutions delivers unsurpassed safety equipment, drastically reducing the risks faced by workers and elevating overall safety standards.

In this insightful blog post, we will explore the vital contributions of BLACKRIDGE Solutions' state-of-the-art gas detection and lone worker safety devices in revolutionizing safety within the agricultural sector. By examining their groundbreaking technologies, benefits, and wider implications, we unravel the essential role of BLACKRIDGE Solutions in enhancing worker protection, farm productivity, and the establishment of safety-centric agricultural workplaces. We will discuss integrating these safety systems with agricultural operations and unravel their impact on various farming aspects, including worker safety, resource management, regulatory compliance, and the cultivation of a proactive safety culture.

Understanding Agricultural Safety Hazards

To optimize agricultural safety, it's crucial to recognize the hazards and challenges workers face in the industry. Some of the primary safety concerns in agricultural settings include:

- Hazardous Gas Exposure: Agriculture workers may encounter dangerous gases, such as ammonia (NH3) from animal waste, hydrogen sulfide (H2S) from manure pits, or methane (CH4) from fermentation processes. Monitoring and controlling gas levels is vital for worker safety.

- Pesticide and Chemical Handling: Farmworkers are responsible for handling and applying pesticides and chemicals, which can pose serious health risks if not managed correctly.

- Machinery and Equipment Operations: Operating farm machinery, such as tractors and combines, can result in injuries or fatalities if proper safety precautions are not in place.

- Lone Workers: Agriculture employees working independently or in vast areas require additional safety measures to ensure prompt assistance during emergencies or accidents.

Agricultural companies can adopt advanced safety devices and best practices to protect their workforce by identifying these hazards.

Optimizing Gas Detection in Agricultural Environments

BLACKRIDGE Solutions provides cutting-edge gas detection technologies designed to enhance the safety of agricultural workers:

- Comprehensive Monitoring and Alerting: Advanced gas detection systems, like BLACKRIDGE Solutions' G7 Gas Detection & Monitoring System, continuously monitor gas levels in agricultural settings and promptly alert workers and supervisors when hazardous concentrations are detected.

- Compliance with Safety Regulations: Implementing premier gas detection solutions helps agricultural operators fulfill safety regulations and demonstrate a strong commitment to safety.

- Data Collection and Reporting: Modern gas detection systems offer real-time data analysis and reporting features, allowing farm managers to continually evaluate and enhance safety procedures, incident tracking, and emergency response plans.

Revolutionizing Lone Worker Safety in Agricultural Settings

Agricultural workers operating alone need specialized safety technology to protect them. BLACKRIDGE Solutions’ G7c and G7x devices by Blackline Safety offers comprehensive lone worker safety solutions equipped with vital features:

- Real-time Location Monitoring: Work-alone devices enable farm managers to track employees' precise locations, which is crucial for providing immediate support during emergencies or accidents.

- Fall and No Motion Detection: Advanced fall and no motion detection capabilities within work-alone safety devices automatically alert supervisors when detecting irregular movements, dramatically improving lone worker safety.

- Instant Emergency Assistance Requests: Workers can rapidly call for assistance during emergencies using their devices' panic buttons and assistance request features.

- Continuous Two-Way Communication: Sustaining communication channels between employees and safety personnel fosters worker confidence and support in high-risk environments.

Integrating Advanced Safety Solutions with Agricultural Best Practices

Agricultural companies can maximize worker safety and productivity by integrating BLACKRIDGE Solutions' advanced gas detection and lone worker safety devices with industry best practices:

- Regular Safety Inspections and Risk Assessments: Routine safety inspections and risk assessments can identify potential hazards and vulnerabilities, enabling farm managers to develop tailored safety strategies.

- Employee Training Programs: Providing comprehensive training on safety devices, safety protocols, and farm-specific hazards ensures the workforce is well-prepared to prioritize safety in their daily tasks.

- Emergency Response Plan Development: Implementing detailed emergency response plans covering hazard identification, equipment usage, and coordinated response procedures significantly enhances agricultural safety outcomes.

- Continual Improvement: Regularly reviewing and refining safety procedures, staying ahead of new technologies, and adapting to regulatory changes are key factors in maintaining a secure agricultural work environment.

Embracing BLACKRIDGE Solutions' Technologies for a Safer Agricultural Landscape

By acknowledging the distinct safety challenges faced by agricultural workers, operators can invest in advanced safety devices and enforce proven best practices that foster secure work environments. BLACKRIDGE Solutions' gas detection and work alone safety technologies, including the G7 Gas Detection & Monitoring System and the Loner series by Blackline Safety, provide essential tools for improving agricultural safety.

By integrating these devices with industry best practices, agricultural operators can ensure worker wellbeing, enhance productivity, maintain regulatory compliance, and promote a proactive safety culture. Contact BLACKRIDGE Solutions today at (778) 686-5799 or [email protected] to learn how their state-of-the-art safety systems can bolster your agricultural business by cultivating a more secure and efficient work environment.

RSS Feed

RSS Feed