Worker Technologies

Uncover the essential role of BLACKRIDGE Solutions top-tier gas detection

and lone worker safety devices in elevating safety standards and operations within the

construction industry. Explore their innovative technologies, benefits, and broader implications

on worker protection, site efficiency, and fostering a safety-driven work environment on

construction sites.

Introduction:

The construction industry is a vital pillar in our global infrastructure, shaping the urban

landscape and contributing significantly to economic development. However, this sector is also

associated with numerous occupational hazards posed by heavy machinery, lone working, and

hazardous substances. In particular, construction workers can face potential exposures to

harmful gases and chemicals on-site, highlighting the importance of just-in-time risk

management and safety equipment to ensure worker protection. Moreover, lone workers on

expansive construction sites require added safety measures to navigate the risks associated

with their remote work environments. Consequently, it is essential for construction companies to

invest in cutting-edge safety technology and best practices designed to safeguard workers and

improve overall workplace safety.

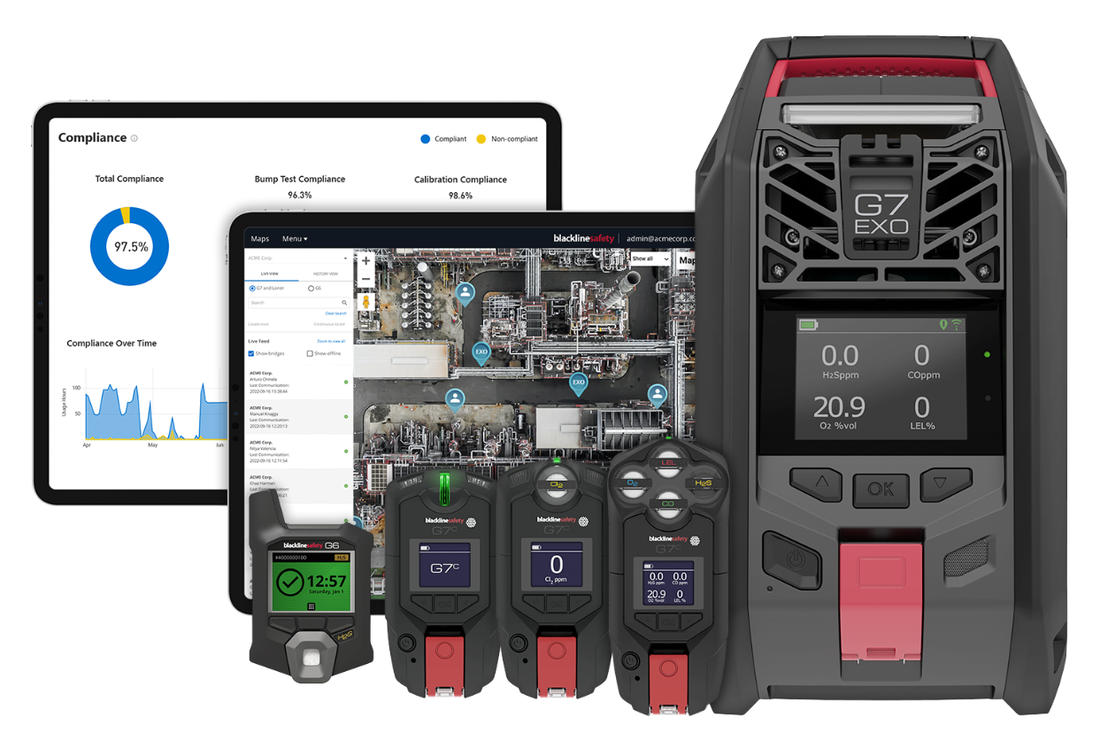

BLACKRIDGE Solutions, a pioneer in lone worker safety and gas detection systems, offers an

acclaimed and award-winning product portfolio specifically designed to address the unique

safety challenges experienced by employees across diverse industries, including construction.

Through rigorous testing and strategic selection of cutting-edge devices from the industry's

leading manufacturers and developers, BLACKRIDGE Solutions delivers unparalleled safety

equipment, substantially reducing risks faced by workers and elevating the overall safety

standards.

In this informative blog post, we will delve into the crucial contributions made by BLACKRIDGE

Solutions state-of-the-art gas detection and lone worker safety devices in revolutionizing the

safety landscape within the construction industry. By examining their ground-breaking

technologies, benefits, and broader implications, we aim to unveil the essential role

BLACKRIDGE Solutions plays in enhancing worker protection, site efficiency, and the

establishment of safety-centric working environments in the construction sector. Additionally, we

will discuss how these safety systems can be seamlessly integrated alongside construction

operations to optimize various aspects of the industry, such as worker safety, resource

management, regulatory compliance, and fostering a proactive safety culture.

Identifying Construction Safety Hazards and Challenges

Before implementing safety measures on construction sites, it is vital to understand the hazards

employees face daily. Some primary safety concerns in the construction industry include:

1. Hazardous Gas Exposure: Construction workers may encounter dangerous gases, such

as carbon monoxide (CO) from generators or vehicles, volatile organic compounds

(VOCs) from adhesives and paints, or methane (CH4) from underground works or pipe leaks.

2. Lone Workers: Construction projects can span vast areas, creating situations where

workers may operate independently, necessitating additional safety measures and

monitoring.

3. Heavy Machinery and Equipment Operations: The use of cranes, excavators, and other

heavy equipment poses inherent risks, requiring robust safety procedures to prevent

injuries or fatalities.

4. Falling Objects and Heights: Construction workers often work at heights or are exposed

to falling objects, leading to dangerous situations that must be managed for their safety.

Recognizing these hazards empowers construction companies to invest in cutting-edge safety

devices and procedures designed to protect their workers.

Integrating Gas Detection Solutions on Construction Sites

BLACKRIDGE Solutions provides industry-leading gas detection technologies to enhance

workers safety in construction settings:

1. Continuous Monitoring and Alerting Systems: Modern gas detection systems, such as

BLACKRIDGE Solutions G7 Gas Detection & Monitoring System, continuously monitor

gas levels and promptly warn workers and supervisors when hazardous concentrations

are detected, ensuring rapid response to potential threats.

2. Ensuring Compliance with Safety Regulations: Adopting advanced gas detection

solutions allows construction operators to demonstrate compliance with safety

regulations and maintain a robust commitment to workplace safety.

3. Real-time Data Collection and Reporting: Gas detection systems featuring real-time data

analysis and reporting enable construction managers to continually evaluate and

enhance safety practices, incident tracking, and emergency response plans, optimizing

safety procedures and outcomes.

Elevating Lone Worker Safety on Construction Sites

Workers operating alone in the construction industry require specialized safety technology to

ensure their protection. BLACKRIDGE Solutions G7 series by Blackline Safety offers

comprehensive lone worker safety devices equipped with essential features:

1. Real-time Location Tracking: Work-alone safety devices enable construction managers

to track individual worker locations, providing vital support during emergencies or

accidents.

2. Fall and Non-Motion Detection: Advanced fall and motion detection capabilities

within work-alone safety devices automatically alert supervisors when unusual

movements are detected, enabling rapid response and intervention.

3. Instant Emergency Assistance: Devices feature panic buttons and assistance request

options, granting workers the ability to call for help quickly during emergencies.

4. Ongoing Two-Way Communication: Maintaining communication channels between

employees and safety personnel fosters worker reassurance and support in high-risk

environments.

Optimizing Construction Safety through Advanced Solutions and Best Practices

Construction companies can enhance worker safety and productivity by integrating BLACKRIDGE Solutions advanced gas detection and lone worker safety devices with industry best practices:

1. Consistent Safety Inspections and Risk Assessments: Regular safety inspections and

risk assessments identify potential hazards and vulnerabilities, allowing construction

managers to devise tailored safety strategies.

2. Comprehensive Employee Training Programs: Training employees on safety devices,

protocols, and site-specific hazards ensures a well-prepared workforce capable of

prioritizing safety in their daily tasks.

3. Collaborative Emergency Response Plan Development: Constructing and implementing

detailed emergency response plans that address hazard identification, equipment usage,

and coordinated response procedures significantly improves construction safety

outcomes.

4. Ongoing Improvement: Periodically reviewing and refining safety procedures, staying

abreast of new technologies, and adapting to regulatory changes are vital components in

maintaining a secure construction work environment.

Conclusion: Harnessing BLACKRIDGE Solutions Technologies for a Safer Construction

Industry

Understanding the unique safety challenges faced by construction workers allows industry

operators to invest in advanced safety devices and implement proven best practices that protect

their employees. BLACKRIDGE Solutions gas detection and lone worker safety technologies, including the G7 Gas Detection & Monitoring System and the G7 Safety series by Blackline Safety, provide the essential tools required to improve safety and well-being for construction workers.

By integrating these devices with industry best practices, construction operators can ensure

worker safety, enhance efficiency, maintain regulatory compliance, and promote a proactive

safety culture. Reach out to BLACKRIDGE Solutions today to learn how their cutting-edge lone

worker safety solutions can bolster your construction business by fostering a more secure and

efficient work environment. [email protected] or (778) 686-5799

RSS Feed

RSS Feed